There are 100types of seam. Here 6types of seams are

discussed that are mostly used in garments. These six types are,

- Super

imposed seam.

- Lapped

seam.

- Bound

seam.

- Flat

seam.

- Decorative

seam.

- Edge

neatening.

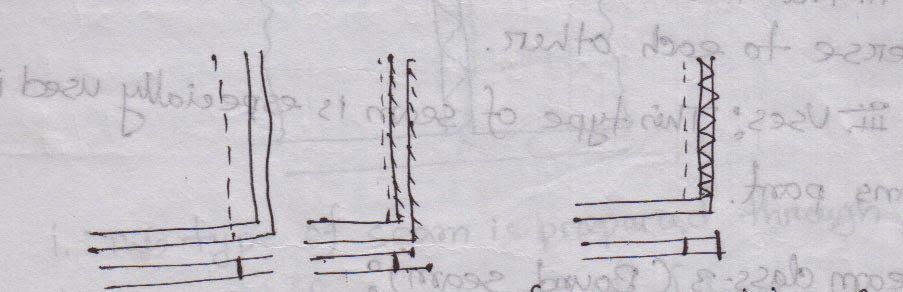

Super imposed seam:

Feature:

i.

Most Commonly used seam.

ii.

This type of seam is formed by correctly placing

the fiber and on the other fabric end.

iii.

Same direction of sewn ends of the fabric.

Uses:

i.

Seam can be used for both joining and edge

neatening.

ii.

Especially this seam is used in side seam of

shirt and trouser.

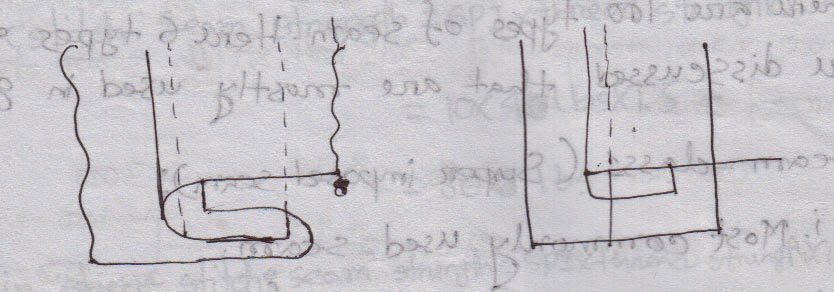

Lapped seam:

Feature:

i.

This type of seam consists of at least two piece

of fabric.

ii.

The two ends sides of both fabrics are reverse

to each other.

Uses:

i.

This type of seam is especially used in jeans

pant.

Bound seam:

Feature:

i.

At least two piece of fabric is required to

produce this seam.

ii.

One side of a fabric is bounded another side of

another fabric.

iii.

Below figure bound seam is widely used in

garments for both functional and decorative purpose.

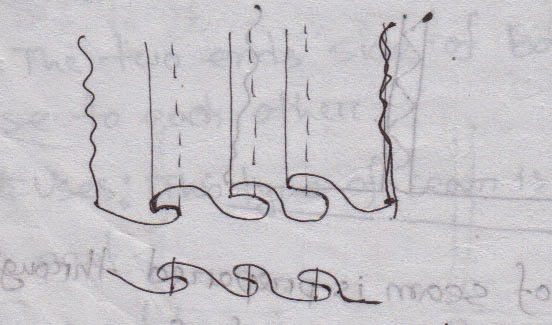

Flat seam:

Feature:

i.

This type of seam is prepared through joining of

the two ends of two pieces of fabric.

ii.

Here no overlapping is done of the fabric rather

the fabric is kept beside to each other.

iii.

Due to lower strength of seam, it is usually

used in knitted and under garments and also for decorative purpose.

Decorative seam:

Feature:

i.

Mainly this type of seam is produced to increase

the beauty of garments.

ii.

This type of seam is prepared by making one or

more that one stitch line on one ply or multiply of fabric.

Uses:

i.

Increased beauty and decorated purpose of

garments.

Edge neatening:

Feature:

i.

This type of seam is mainly prepared in selvedge

of the fabric in such a way that threads can not come out from the end of

fabric.

ii.

This type of seam is mostly used in garments.

Costing is a

process by which to set a price of a product is calculated by considering all

the related factors. Doing Cost Analysis is a very important task for a factory

which runs for business purposes. Costing of the products considering the raw

material expenditure, salary of officers and workers, distributions and

advertisement expenses etc. all direct and indirect expenses is considered very

honestly. It is determined by a troop of accountants with advice and

consultancy of executive director.

Costing is a

process by which to set a price of a product is calculated by considering all

the related factors. Doing Cost Analysis is a very important task for a factory

which runs for business purposes. Costing of the products considering the raw

material expenditure, salary of officers and workers, distributions and

advertisement expenses etc. all direct and indirect expenses is considered very

honestly. It is determined by a troop of accountants with advice and

consultancy of executive director.